ANTI-TERMITE TREATMENT OF FOUNDATIONS

The

subject of anti-termite treatment of buildings is usually divided into the

following three parts:

1.

Pre-construction measures to be taken

2.

Pre-construction treatment

3.

Post-construction treatment

IS 6313 Part 1 deals

with the general constructional measures to be taken, Part 2 deals with pre-construction treatment and Part 3 discusses post-construction

treatment (treatment of existing buildings). They give many constructional

features to be provided in buildings such as for godowns, etc. to reduce

termite attacks which we will not deal with in this book. Here we will consider

only pre-construction and post-construction treatments of ordinary buildings.

Termites in Buildings

Based

on their habitat, termites are classified into the following two types:

1.

Ground nesting or subterranean termites

2.

Wood nesting or non-subterranean termites

Ground

nesting or subterranean termites are more common in India and their presence in

and around a building is indicated by swarms of winged reproductions flying

from the soil or wood lying around the site just at the beginning of the

monsoon.

Wood

nesting or non-subterranean termites live in the dry wood inside buildings and

is recognized by their pellets of digested food or blisters on the wood surface

as the wood is eaten away. In their search for food, these termites damage not

only wood (cellulose) but also substances like rubber, plastic, underground

cables, etc. Both varieties can be terminated by the same anti-termite

chemicals.

Recommended

Chemicals for Treatment

Even though Aldrin, DDT and many

other chemicals were once prescribed in old IS codes, many of them were found

to be very toxic and leave toxic residues in the soil and ground walls which

give health problems over a period of time. Hence many of them have now been banned

in the new revision of the BIS code. The following emulsifiable chemicals have

now been recommended:

1. Chloropyrifos concentrate 1.0% by weight

2. Heptachlor concentrate 0.5% by weight

3. Chlordane concentrate 1.0% by weight

Chlorpyrifos in 1%

concentration by weight conforming to IS8944 (1978) is a popular chemical being

used. They are available with agrochemical agencies as they are used to control

termites in crops such as cotton, coconut, citrus, etc. Durmet is a brand name

of one of the chlorpyrifos available in the market in various concentrations. Another brand name is Dustban TC. These

can be diluted to form 1% concentration as desired in water for soil treatment

and in kerosene oil for treatment of wood.

Generally, 5 parts of Durmet 20

EC are diluted with 95 parts of water (or kerosene) to give an emulsion of 1%.

As the solution is toxic, if it comes in contact with the skin, it should be

washed out immediately with soap and water. The methods of treatment

(pre-construction treatment and post-construction treatments) are briefly

described below.

Pre-construction

Treatment with Durmet

A hand-operated pump is used for

uniformly spraying the chemicals at the specified rate. To facilitate the

right dose, graduated containers should be used. Treatment should not be

carried out when it is raining or soil is wet with subsoil water. It should

start when foundation trenches and pits are ready and just before concreting of

the foundation. The treated barriers for termites should not be disturbed after

treatment. The treatment is shown in Fig. below and is carried out in seven stages

as described further.

First stage: Treatment of wall trenches and basement excavation. As the first step, all

termite hills found at the site during site clearance should be sprayed with

chemicals. All surfaces of pits (sides

and bottom of wall trenches and basement excavations) should be treated to

a height of 30 cm from the bottom with the solution at the rate of 5 litres per

square metre of surface area.

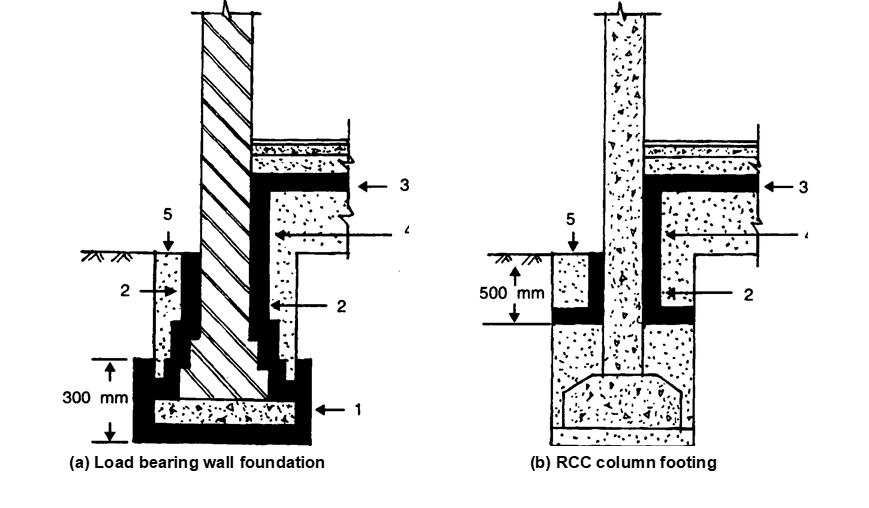

Anti-termite treatment of foundation

and earth fill below the ground floor.

Second stage: Treatment of refill in contact with the foundation. All the

refilled earth in the excavation is immediately in contact with both sides of the

wall footing and all four sides of a column footing should be treated for a

distance of 30 cm (as shown in Fig. above) at the rate of 3 to 5 litres per

linear metre vertical surface of the wall. If water is used for ramming the

earth, then treatment should be done after the consolidation by rodding (making

holes) in the consolidated earth at close intervals of 15 cm close to the wall

or columns and applying the chemical close to the wall. It is preferable to

treat all the earth adjacent to the foundation for a width of 30 cm. Similarly

in framed structures, excavations for the plinth beams should also be treated.

Third stage: Treatment of soil below floors. The earthfill below the

floors up to the plinth level has also to be treated after the fill has been

made by putting holes 5 to 7.5 cm deep at 15 cm centres in a grid pattern and

filling the holes with the solution at the rate of 5 litres per square metre of the treated surface.

Fourth stage: Treatment of junction of floor and wall. Before laying

the subgrade, channels of 3 cm wide and 3 cm deep are dug along the junctions

of floor and wall and treated at 15 litres per square metre of wall surface by

putting holes 15 cm apart along the channel and allowing the chemical to

seep through to the bottom. The soil is tamped back in position after the

operation.

Fifth stage: Treatment of soil along the external perimeter of the building.

After the building is completed, holes are made along the external perimeter at

intervals of 15 cm and depth of 30 cm. These holes are filled with the chemical

emulsion at the rate of 5 litres per metre length of the wall.

Sixth stage: Treatment of other locations. Anti-termite treatment

should be made at expansion joints after the subgrade has been laid at 2 litres

per linear metre of expansion joint. Similarly, when pipes and conduits enter

the building, the soil around them for a distance of 15 cm and a depth of 7.5 cm

should be loosened and treated.

Seventh stage: Treatment of wood surfaces. It is also a good practice

to paint all fresh wood surfaces, such as door and window posts which will be

in contact with masonry, with two coats of the chemical in kerosene oil before

it is installed in the building.

Post-construction Anti-termite Treatment of Building

Foundation

For

post-construction operation, a pressure pump will be required for proper

penetration of chemicals into the surface to be treated. Proper checks should

also be made regarding the adequacy of the number of chemicals (chemicals

mixed with water) pumped in. The following procedure is usually adopted:

Treatment of foundation of outside

walls around the building. If there is no

apron, we make trenches 50 cm deep and equal to the width of a shovel, exposing

the foundation near the external walls. Holes 15 cm apart and 50 cm deep are

made by an iron rod. Emulsion at the rate of 5 litres per square metre of the vertical surface of the substructure is to be used for each side of the floor.

One-half of the quantity is pumped through the holes and the other half is

poured along the trench. If there is a concrete apron, 12 mm diameter holes are

dug as close to the wall as possible about 30 cm apart and the chemical is

pumped into these holes at the rate of 5 litres per linear metre. A similar treatment is to be made for column and plinth beams.

Treatment of soil under floors. For this purpose, 12 mm diameter holes 30 cm apart are

made deep enough to reach the soil below along the junctions of wall and floor,

along cracks in the floor and along the construction joints. The emulsion with

water is pumped into these holes to soak the soil or at the rate of one litre

per hole. The holes are then sealed with cement mortar 1:2. (The floor may

also be drilled and the ground below treated but this is a cumbersome process.)

Treatment of masonry at plinth level. The movement of termites through the walls can be

stopped by drilling holes in the masonry at plinth level at an angle of 45° on

both sides of the wall (and especially where wood such as door post is present)

at 30 cm centres. The emulsion is pumped till the masonry is soaked or at a

maximum of one litre per hole. The holes are then sealed with 1:2 cement

mortar.

Post-construction Treatment of Woodwork

In

post-construction, we may have to deal with buildings in which the woodwork

such as doors or fittings (such as shelves) have been attacked by termites

It

is better to treat woodwork with the chemical mixed in kerosene oil. Through this

process, we get better penetration of the chemical into the wood. First, the

masonry around the wood is treated with the chemical and secondly the wood

itself is treated by drilling 6 mm diameter holes at 15 cm intervals and

infusing it with the kerosene-based chemical. Two coats of the chemical can

also be applied to the surface of the wood before applying the paint.

Must read: Anti-Termite

Treatments For Types Of Construction Works

FAQ

Which chemical is used in anti-termite treatment?

1. Chloropyrifos

concentrate 1.0% by weight

2. Heptachlor

concentrate 0.5% by weight

3. Chlordane

concentrate 1.0% by weight

Drug Rehab Nashville: Drug rehab centers in Nashville provide a comprehensive approach to recovery, including detox, therapy, and support services.

ReplyDeleteThe personalized treatment plans in rehab centers ensure that each individual's needs are met.

ReplyDeleteAddiction is a complex disease that affects individuals physically, emotionally, and spiritually. As more people recognize the need for a comprehensive approach to recovery, holistic addiction treatment programs have emerged as a viable option for many. These programs focus on treating the whole person, rather than just the addiction, by integrating traditional therapeutic techniques with alternative healing practices. This article explores what holistic addiction treatment programs entail, their benefits, and how they can support individuals on their journey to recovery.

ReplyDelete