Estimating Costs and Material Requirements for Your Home

| Guide of Home Construction Material and Cost Estimation | How do you estimate

the materials needed to build a house?

It is always worthwhile to estimate the cost of the proposed construction so that it does not exceed the available finances. We have already seen in the article “Classification of Buildings” how a building can be classified as class I, II or III. If the approximate cost to build a building of a particular class in a given locality is known the total cost of the building, can be estimated on an area basis. In this article, we will examine the various components of the cost of the building so that we can control the cost during the execution stage itself. Charges for supervision and the supply of labour and materials which are paid for by the owner are usually taken as 7 to 10% of the overall cost of the building. In lump sum and item-wise contracts, because of the new tax laws, contractors expect a profit of 15 to 20% of the cost of the work.

BREAK UP OF COST OF

CONSTRUCTION

The table below gives the approximate average

percentage cost of civil works for a residential building. It also

indicates the possible savings that can be made. The actual values will depend

on many factors like foundation condition and architectural features.

Table: Percentage cost of civil works

|

S.No. |

Works |

Cost (% of the total

cost) |

Possible savings (% of the total

cost) |

|

1. |

Foundation and plinth |

10 to 15 |

1 to 3 |

|

2. |

Superstructure |

|

|

|

|

(wall + roof, including plastering) |

30 to 40 |

4 to 13 |

|

3. |

Painting |

5 to 20 |

1 to 8 |

|

4. |

Doors and windows |

12 to 20 |

1 to 8 |

|

5. |

Flooring |

10 to 20 |

2 to 7 |

In

addition, the cost of services is usually estimated as a percentage of civil

works and is taken as follows:

|

Water supply and sanitation |

10 to 12.5 per cent |

|

Electrical works |

8 to 12.5 per cent |

|

External works |

2 to 5 per cent |

|

Total |

20 to 30.0 per

cent (max) |

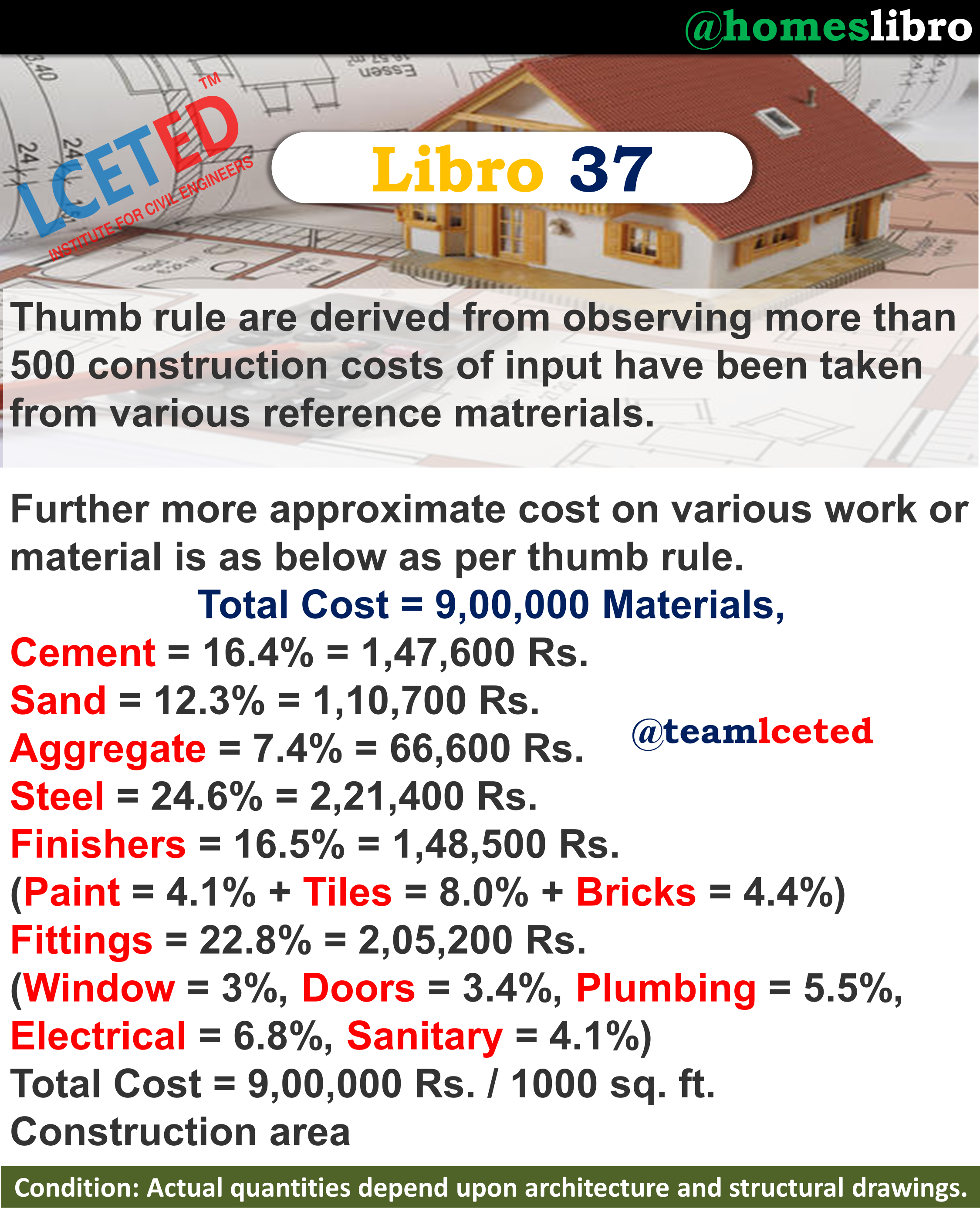

RATIO OF COST OF

MATERIALS TO LABOUR

It

has been found that the total cost can be divided

into the following percentages for

an ordinary building built in India in the traditional way:

1. Material cost - 60 per cent of the

total cost

2. Labour cost - 30 per cent of the

total cost

3. Other costs - 10 per cent of the

total cost

The

break up of the cost of materials can be approximated as given in the Tables below

Cost of principal materials

|

S.no |

Item |

Approximate cost

as % cost of the civil work |

|

1. |

Bricks |

15 to 18 |

|

2. |

Cement |

12 to 18 |

|

3. |

Steel |

5 to 15 |

|

4. |

Timber |

10 to 15 |

|

5. |

Sand |

7 to 10 |

|

6. |

Aggregate |

8 to 10 |

|

7. |

Paint |

5 to 10 |

Cost of labour

|

S.no |

Worker |

Approximate cost

as % of civil works |

|

1. |

Mason |

12 |

|

2. |

Unskilled labour |

12 |

|

3. |

Carpenter |

6 |

CONSUMPTION OF MATERIALS

FOR BUILDINGS

The

data given in the Table below can be taken as very approximate quantities of materials required for construction of an ordinary

building.

Table: Very approximate quantities of

materials required for a 1 m2 plinth area

|

S.No. |

Materials |

Quantity per m2

of plinth area |

|

1. |

Bricks

(9" ordinary) |

250-300

nos. |

|

2. |

Sand |

0.5

to 0.7 m3 |

|

3. |

40

mm aggregates |

0.2

m3 |

|

4. |

20

mm aggregates |

0.2

m3 |

|

5. |

Steel

for buildings with load bearing walls |

10

to 20 kg |

|

6. |

Steel

for framed flats and hostels |

30

to 50 kg |

|

7. |

Steel

for framed offices |

40

to 70 kg |

|

8. |

Cement

for load bearing walls |

3

bags |

|

9. |

Cement

for framed buildings |

4

bags |

|

10. |

Lime

for brick jelly |

40

litres |

ANALYSIS OF ITEMS OF

WORKS

The

quantities of important items of work

for buildings can be worked out to control cost as shown in the Table below

which is for a middle-class building

on load bearing walls. The values shown are not exact but only indicative.

Table: Items of works for residential buildings on

load-bearing walls (Quantitative are only indicative. Actuals will depend on

the design.)

|

s.no |

Materials |

Approximate

quantity per m2 of the plinth area |

|

|

G.F ONLY |

G.F + F.F |

||

|

1 |

Earthwork |

0.52 m3 |

0.30 m3 |

|

2 |

Mass concrete in foundation and under

floor |

0.22 m3 |

0.15 m3 |

|

3 |

RCC in foundation |

0.11 m3 |

0.06 m3 |

|

4 |

Brickwork in foundation (varies) |

0.16 m3 |

0.09 m3 |

|

5 |

Brickwork in superstructure |

0.40 m3 |

0.40 m3 |

|

6 |

RCC in superstructure: |

|

|

|

Plinth/lintel/beam |

0.05 m3 |

0.05 m3 |

|

|

Slab and stairs |

0.01 m3 |

0.18 m3 |

|

|

Sunshade/shelves |

0.18 m3 |

0.01 m3 |

|

|

7 |

Doors and windows |

0.45 m3 |

0.45 m3 |

|

8 |

Plaster |

2.60 m3 |

2.60 m3 |

|

9 |

Painting of walls and ceiling |

3.5 m3 |

3.5 m3 |

|

10 |

Waterproofing |

0.98 m3 |

0.60 m3 |

|

11 |

Flooring |

0.75 m3 |

0.75 m3 |

CEMENT REQUIREMENTS IN

CEMENT WORKS

Cement

is an important material and its consumption must be controlled. Some of

the data used for the calculation of cement requirements in concrete, mortar and

plaster are given in the Tables below

Table: Cement consumption for concrete

|

Mix |

W/c ratio |

Strength |

Cement per (m3

of concrete (kg) |

|

|

With control |

Without control |

|||

|

1 :1.5: 3 |

0.42 |

20 |

30 |

405 |

|

1 : 2 : 4 |

0.55 |

15 |

25 |

310 |

|

1 : 3 : 6 |

0.75 |

10 |

15 |

215 |

|

1 : 4 : 8 |

Used only for base concrete, etc. |

160 |

||

|

1 : 5 : 10 |

Used only for base concrete, etc. |

130 |

||

Note:

1 cubic metre = 35.315 cubic feet; Approximate yield = 2/3 x Volume of mix.

Hence, volume of cement required per m3 of concrete is taken as (1.52/ Volume of mix) (approx).

Table: Requirements for 1 m3

of cement mortar

|

Mix of mortar |

Cement (bags) |

Sand (m3) |

|

1:3 |

2.6 |

0.267 |

|

1:4 |

1.9 |

0.275 |

|

1:6 |

1.4 |

0.299 |

|

1:8 |

1.1 |

0.308 |

Note:

For brick masonry, we need 500 metric

bricks (and 520 ordinary bricks) per cubic metre of brickwork and 25 to 30% of the volume of brickwork

will be taken up by a mortar. Hence, we need about 0.25 to 0.30 cft of mortar. One bag of cement is considered as 50

kg in weight and 35 litres in volume.

Table: Requirements for 100 m2

of 12 mm thick cement plaster

|

Mix |

Cement

(bags) |

Sand

(m3) |

|

1 : 2 |

21 |

1.4 |

|

1 : 3 |

15 |

1.5 |

|

1 : 4 |

12 |

1.6 |

|

1 : 6 |

9 |

1.8 |

Note:

1 square metre = 10.764 square feet

ESTIMATION OF STEEL IN RC

WORKS

For preliminary estimation, it is usual to assume the steel requirement on a percentage basis (or kg/m3)

of the easily calculable volume of concrete based on the data given in Table below.

The actual requirement by proper design will be much less.

(Note: Steel rods usually come in

lengths of 11 m. Hence we can check the weight of a consignment by counting the

rods. For example, the weight of a consignment consisting of 8 rods each of length 11 m = 11 x 0.395 =

4.4 kg, approximately.)

Table: Estimation of steel in buildings

components (Fe 415 steel)

|

Item |

Coefficients

for estimation of steel |

|

|

As

% of steel |

As

Kg/m3 |

|

|

Footings |

0.25 to 0.65 |

20 to 50 |

|

Cast In-situ Piles |

0.40 to 0.75 |

30 to 60 |

|

Rafts |

0.75 to 1.50 |

60 to 120 |

|

Columns |

1.00 to 4.0 |

80 to 320 |

|

Beams |

0.5 to 1.5 |

30 to 100 |

|

Slabs and lintels |

0.3 to 0.6 |

25 to 50 |

|

Sunshades |

0.3 to 0.5 |

25 to 30 |

Note:

1% steel = 78.5 (say 80 kg) of steel per cubic metre of concrete.

Example: Find the steel required for a slab 15 x 10 m and 120 mm

thick.

Volume of concrete = 15 x 10 x 0.12 = 18 m3

Assume % of steel is 0.4 % = (or 0.4 x 78.5 = 31 kg/m3)

Wt of steel = 18 x 31 = 565 kg

(Note: This works out to 565 ÷ 150 =

3.76 kg/m2 for slab only. In addition we have foundation beams, columns etc. so

that the total quantity will workout to 10 to 20 kg/m2)

TYPICAL MINIMUM

CONSUMPTION

The

minimum consumption of steel in kg/m2

by proper design and detailing for a typical four storey building on good

soil using to Fe 415 steel can be a

total of 20 kg/m2 as

follows

Minimum steel for a four-storey flat

|

ITEM |

STEEL

CONSUMPTION |

|

Foundation |

2.0 kg/m2 |

|

Plinth beam |

2.0 kg/m2 |

|

Columns |

4.0 kg/m2 |

|

Beams |

5.0 kg/m2 |

|

Slabs and stairs |

5.5 kg/m2 |

|

Lintels, sunshade etc. |

1.5 kg/m2 |

ANALYSIS OF RATES

One

of the topics studied in "estimating"

is the analysis of the rates of various items of works. The data for the cost of

materials, labour and other items such as scaffolding required per unit of work

for each item of work in each region of the country is available. From these

data, the cost per unit of work can be estimated. As it is a subject to be studied underestimating, we will not go into

a detailed study of the subject in this article.

ESTIMATION OF PAINT

REQUIRED FOR PAINTING AN AVERAGE RESIDENTIAL BUILDING

(a) Rough estimate of areas to be

painted in terms of plinth area: Area of ceiling = Floor area (say plinth area)

Area

of internal walls = 3 x plinth area

Area

of external walls = 2 x plinth area

Area

of windows = 30% plinth area on each side

Area

of doors = 30% plinth area each side

(b) Approximate coverage of different

types of paints per coat (Second and third coats will have 25% more coverage).

1.

Fat lime for lime-washing 10 m2/kg

(For

colour wash add 1 to 2 kg colour per 100 m2)

2.

Dry distemper 10 m2/kg

3.

Cement paint 5 m2/kg

4.

Cement wall primer 8 m2/L (litre)

5.

Oil bound distemper 8 m2/kg

6.

Plastic emulsion paint 10 m2/L

7.

Acrylic exterior paint 12 m2/L

8.

Metal primer 10 m2/L

9.

Synthetic caramel paint 10 m2/L

10.

Copal varnish for wood 10 m2/L

MUST READ: Cost

Percentage Of Building Materials For 1000 Sqft of House Construction

MUST READ: Material

and labour Cost of One Room Construction | Room Estimation

FAQ

How Much Paint do I Need?

Example: Find the approximate quantity of paint required for

painting 200 m2 of wall with plastic emulsion paint in two coats.

Paint

required for first coat = (200/10) = 20.0 litres

Paint

required for second coat = 16.0 litres (10% less)

Total

= 36.0 litres (approx)

Note:

Generally one painter can be assumed to paint 15-20 m2 of wall

surface per day, depending on the type of paint and finish.

How much paint do I need for one coat?

Approximate coverage of different types

of paints per coat (Second and third coats will have 25% more coverage).

1.

Fat lime for lime-washing 10 m2/kg

(For

colour wash add 1 to 2 kg colour per 100 m2)

2.

Dry distemper 10 m2/kg

3.

Cement paint 5 m2/kg

4.

Cement wall primer 8 m2/L (litre)

5.

Oil bound distemper 8 m2/kg

6.

Plastic emulsion paint 10 m2/L

7.

Acrylic exterior paint 12 m2/L

8.

Metal primer 10 m2/L

9.

Synthetic cramel paint 10 m2/L

10.

Copal varnish for wood 10 m2/L

What is rate analysis?

One of the topics studied

in "estimating" is the analysis of the rates of various items of works.

The data for the cost of materials, labour and other items such as scaffolding

required per unit of work for each item of work in each region of the country

is available. From these data, the cost per unit of work can be estimated.

How many cement bags are used for

plastering?

Requirements for 100 m2 of

12 mm thick cement plaster

|

Mix |

Cement

(bags) |

Sand

(m3) |

|

1 : 2 |

21 |

1.4 |

|

1 : 3 |

15 |

1.5 |

|

1 : 4 |

12 |

1.6 |

|

1 : 6 |

9 |

1.8 |

Note:

1 square metre = 10.764 square feet

What is the percentage of cost of

materials and Labour?

1. Material cost - 60 per

cent of the total cost

2. Labour cost - 30 per

cent of the total cost

3. Other costs - 10 per

cent of the total cost

How much steel is in a building?

Estimation of steel in buildings

components (Fe 415 steel)

|

Item |

Coefficients

for estimation of steel |

|

|

As

% of steel |

As

Kg/m3 |

|

|

Footings |

0.25 to 0.65 |

20 to 50 |

|

Cast In-situ Piles |

0.40 to 0.75 |

30 to 60 |

|

Rafts |

0.75 to 1.50 |

60 to 120 |

|

Columns |

1.00 to 4.0 |

80 to 320 |

|

Beams |

0.5 to 1.5 |

30 to 100 |

|

Slabs and lintels |

0.3 to 0.6 |

25 to 50 |

|

Sunshades |

0.3 to 0.5 |

25 to 30 |

How to Calculate Construction Cost per Square Feet?

Thank you for help us to know the how the construction cost and material estimation cost will be for house. It is use full. Brainstorm Infotech is headquartered in Bengaluru, the start-up capital of India. It has carved a niche for itself in the field of structural steel detailing and allied services with a credit of completing over 1250 projects so far. We started small with a team of five professionals in 2010 but have earned the trust and respect of our clients that has led to long-standing associations.https://www.brainstorminfotech.co.in/

ReplyDelete"Your art has such a calming effect—it's like it transports me to another place." painters kew east

ReplyDelete